KEENAN VA 3- 36

KEENAN VA 3- 36

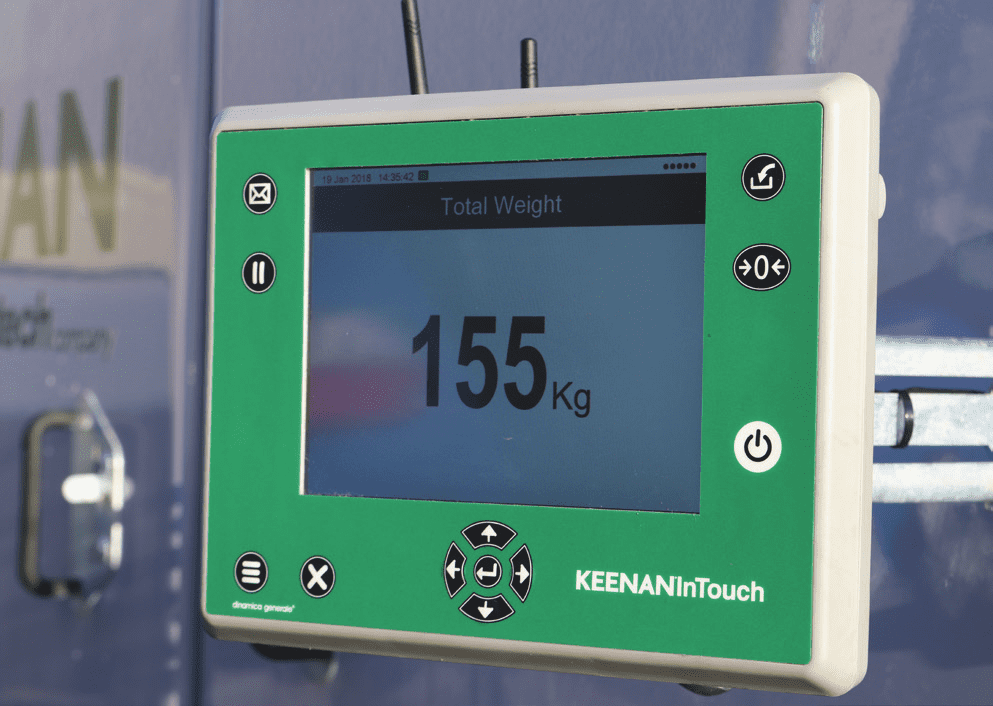

The KEENAN VA3 36 is designed to meet the feeding demands of the largest dairy and beef units globally. Fitted with three augers, this range of vertical feeders are longer and narrower than their VA2 counterparts, and come with a range of feed out options. All machines in the KEENAN VA3 range are supplied as standard with the In Touch controller, guaranteeing an optimal TMR through precise loading and mixing times.

Key Features

- Discharge: Front right hand side and rear left and side discharge with trays for dual feedout

- Speed: Engineered to optimise use of space, by allowing materials to be rapidly and efficiently mixed into the overall mixed ration.

- Capacity: The efficient use of space means that this machine may load and mix the full volumes of material consistent with their declared capacity.

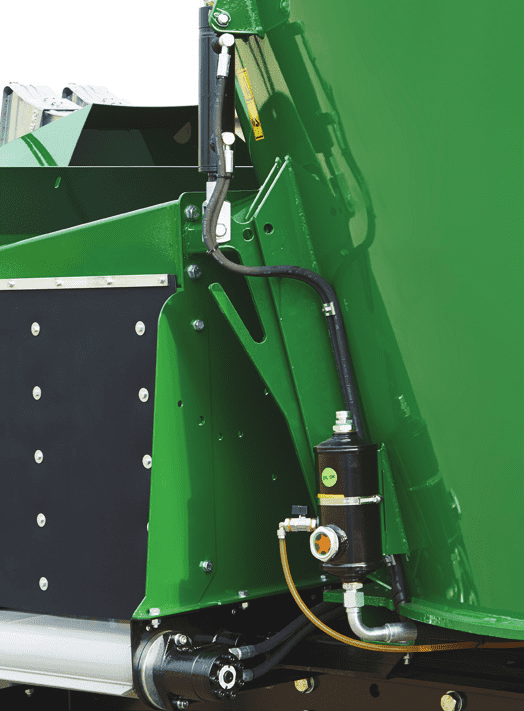

- Heavy Duty Auger and Blades: Fitted with a heavy duty auger as standard. The triangular blades are fitted with a long lasting tungsten coating which increases their longevity. The additional two blades are fitted towards the top of each auger ensuring rapid incorporation of bales.

- Inspection platform: Fitted as standard this machine offers an inspection platform for viewing the mix.

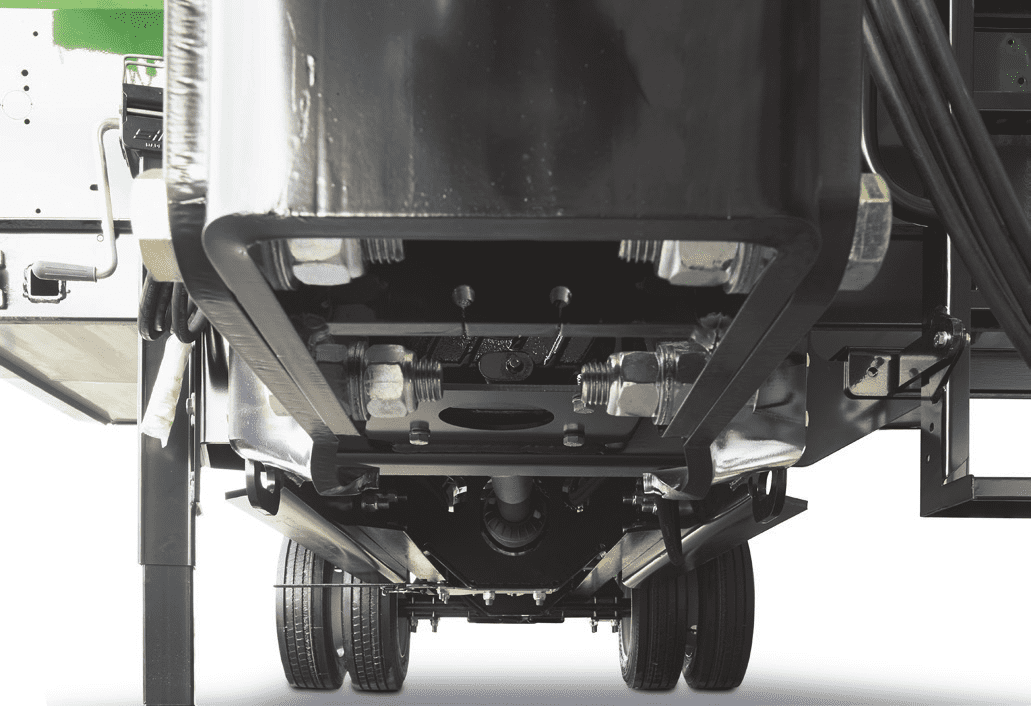

- Heavy Duty Chassis: This machine is mounted on a custom-built heavy duty chassis. Its robust construction ensures durability and reliability even under the toughest conditions.

- Hay Ring: This machine is fitted with a hay ring to prevent overflow of material.

- Footprint and Handling: This machines footprint is designed to allow them to fit into most modern farmyard buildings, making them an extremely manoeuvrable machine.

- Air brakes

Optional Extras

- Two side discharge doors located at both the front and rear of the machine

- Font mounted discharge conveyors

- Elevator extensions for front discharge conveyors which helps to achieve additional discharge height

- Magnet kit to capture steel debris

- Viewing camera with screen in tractor cab for improved visibility

- Wide Angle PTO

Farm Compare User Rewards- With Every Enquiry:

* Receive a complimentary review from the InTouch and KEENAN technical advisors.

With Every Purchase:

* (NI & ROI & GB) 1 free service.

* (NI & ROI) 1-year free subscription to the InTouch feed management technology.

* (NI & ROI) 2 free visits from your regional InTouch feeding specialist.

* (GB) An exclusive KEENAN Driver Pack which includes; winter jacket, set of coveralls, beanie hat, insulated mug and Britains® MechFiber 365 1:32 replica model.

*Finance options available including 6-month 0% interest deferred payment subject to status. Terms and conditions apply.

*First time KEENAN users can gain €24,400 in their first year

KEENAN offer a combination of technology and advisory nutrition support to drive feed efficiency and utilisation on farm. According to the IFAC survey only 32% of farms are currently using technology to increase farm efficiencies with 52% mentioning cost as a barrier. With all investment there needs to be a return of investment and first-time users of KEENAN technology increased their feed efficiency by 11% through increased productivity and reduced feed costs, resulting in an extra €244 per cow per year – €24,400 for a herd of 100 cows. More info here

Specification for KEENAN VA 3- 36

Leave a Review

Every KEENAN machine around the world is made in our purpose built factory in Borris, County Carlow, Ireland

We pride ourselves on our precision built diet feeders, made in our factory in Borris, Carlow by our skilled welders and fabricators. As well as new machines, we have a small range of Approved Used diet feeders available.

Ask a Question

-

Description

The KEENAN VA3 36 is designed to meet the feeding demands of the largest dairy and beef units globally. Fitted with three augers, this range of vertical feeders are longer and narrower than their VA2 counterparts, and come with a range of feed out options. All machines in the KEENAN VA3 range are supplied as standard with the In Touch controller, guaranteeing an optimal TMR through precise loading and mixing times.

Key Features

- Discharge: Front right hand side and rear left and side discharge with trays for dual feedout

- Speed: Engineered to optimise use of space, by allowing materials to be rapidly and efficiently mixed into the overall mixed ration.

- Capacity: The efficient use of space means that this machine may load and mix the full volumes of material consistent with their declared capacity.

- Heavy Duty Auger and Blades: Fitted with a heavy duty auger as standard. The triangular blades are fitted with a long lasting tungsten coating which increases their longevity. The additional two blades are fitted towards the top of each auger ensuring rapid incorporation of bales.

- Inspection platform: Fitted as standard this machine offers an inspection platform for viewing the mix.

- Heavy Duty Chassis: This machine is mounted on a custom-built heavy duty chassis. Its robust construction ensures durability and reliability even under the toughest conditions.

- Hay Ring: This machine is fitted with a hay ring to prevent overflow of material.

- Footprint and Handling: This machines footprint is designed to allow them to fit into most modern farmyard buildings, making them an extremely manoeuvrable machine.

- Air brakes

Optional Extras

- Two side discharge doors located at both the front and rear of the machine

- Font mounted discharge conveyors

- Elevator extensions for front discharge conveyors which helps to achieve additional discharge height

- Magnet kit to capture steel debris

- Viewing camera with screen in tractor cab for improved visibility

- Wide Angle PTO

Farm Compare User Rewards- With Every Enquiry:

* Receive a complimentary review from the InTouch and KEENAN technical advisors.With Every Purchase:

* (NI & ROI & GB) 1 free service.

* (NI & ROI) 1-year free subscription to the InTouch feed management technology.

* (NI & ROI) 2 free visits from your regional InTouch feeding specialist.

* (GB) An exclusive KEENAN Driver Pack which includes; winter jacket, set of coveralls, beanie hat, insulated mug and Britains® MechFiber 365 1:32 replica model.*Finance options available including 6-month 0% interest deferred payment subject to status. Terms and conditions apply.

*First time KEENAN users can gain €24,400 in their first year

KEENAN offer a combination of technology and advisory nutrition support to drive feed efficiency and utilisation on farm. According to the IFAC survey only 32% of farms are currently using technology to increase farm efficiencies with 52% mentioning cost as a barrier. With all investment there needs to be a return of investment and first-time users of KEENAN technology increased their feed efficiency by 11% through increased productivity and reduced feed costs, resulting in an extra €244 per cow per year – €24,400 for a herd of 100 cows. More info here -

Specifications

3100mm 6650mm 10580mm 36m3 Passage Trough Vertical Large Farm Dairy Beef Sheep N/A 156-210 N/A N/A -

Reviews

This product has no reviews.Leave a Review

-

Q&A's

Question: I have a dead end feed passage how can I feed out? Answer:We have the ability to customise each machine with a variety of feed out options. We can fit a rear feed out conveyor which has the ability to feed out on two sides simultaneously at the rear of the machine. We have solutions for each application.

Question: Where are Keenan machines made? Answer:Every KEENAN machine around the world is made in our purpose built factory in Borris, County Carlow, Ireland

Question: Do you only sell new feeders? Answer:We pride ourselves on our precision built diet feeders, made in our factory in Borris, Carlow by our skilled welders and fabricators. As well as new machines, we have a small range of Approved Used diet feeders available.

Ask a Question

-

Attachments

-

Images

-

Videos

We have the ability to customise each machine with a variety of feed out options. We can fit a rear feed out conveyor which has the ability to feed out on two sides simultaneously at the rear of the machine. We have solutions for each application.